Weighing and Batching

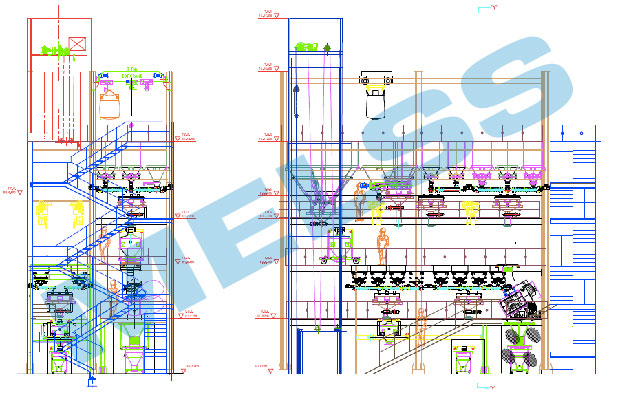

MELSS can supply the complete batching system for industrial batching plants, including weigh hopper/tank, storage tank, pneumatic conveying equipment, valves & gates apart from other material handling equipment, thus providing a one-stop solution for weighing and batching requirements.

Handling of bulk materials needs to be processed in a specialised way. Batching refers to the production of materials in batches to achieve the high volume target, and finds use in any industry needing mixing, preparation and storage of materials in bulk. The processing involves the use of silos, hoppers and conveyors for large volume storage, processing and movement of materials, ably supported by automation software using PLC and SCADA for best results.

MELSS has been providing customised batching solutions for the batching plant to a variety of industries for the last 25 years, with expertise in both hardware and software. Whatever be the form of materials – powders, granules, pellets, flakes or liquids, we have created custom solutions for each category

Weighing and Batching Plant

Weighing and Batching systems are critical in many fields of industrial production, and MELSS’ solutions in this area cater to the wide range of industries and their specific batching requirements with absolute reliability and maximum precision.

- Product quality

- Weighing accuracy

- Increase productivity

- Process optimisation

- Report generation

- Ensured safety

In order to achieve all the above in the manufacturing industry, MELSS offers customised Automatic Batching solutions.

We provide batching systems by integrating and controlling storage, loading and unloading mechanisms with a programmable logic con

troller (PLC) and by using a SCADA/HMI.

Weighing and Batching Plant

We provide batching systems by integrating and controlling storage, loading and unloading mechanisms with a programmable logic controller (PLC) and by using a SCADA/HMI.

Manufacturing is carried out using leading-edge technology and factory-tested raw materials, and a series of stringent inspections under surveillance is also performed on the entire range of products to ensure complete freedom from defects.

Benefits

- Compact Design

- Reliability

- Durable

Any process involving proportional mix of 2 or more ingredients can be achieved by incorporating a Batch Weighing System.