Have your PIC-based devices been tested reliably and quickly?

Photonic Integrated Circuit (PIC) solutions are being adopted by manufacturers to address the reduced size and complexity challenges while also addressing heat management issues experienced in today’s data centres. Frantic development of smaller, faster, cheaper and greener transceivers/active components and passive components is driving the development of high-speed networks and 5G, Photonic Integrated Circuits (PICs).

Passive optical components used in optical systems operate without external power or active control. They use processes such as transmission, reflection, polarisation, coupling, splitting, filtering, and attenuation to alter light signals.

Need for Testing

A PIC is composed of many optical components such as optical couplers, fibre-optic switches, splitters, attenuators, wavelength-division multiplexers, and transceivers.

Testing of any PIC-based device is needed in all life cycle stages — from design and development, and qualification to validation of production.

Testing – The Requirements

Automation, repeatability, scalability and parallelisation of the testing processes are needed for the huge volume of circuits and ports, to be able to meet the profitability of economies of scale. Photonics labs must evolve with the optical test requirements of passive (guiding light) optical components.

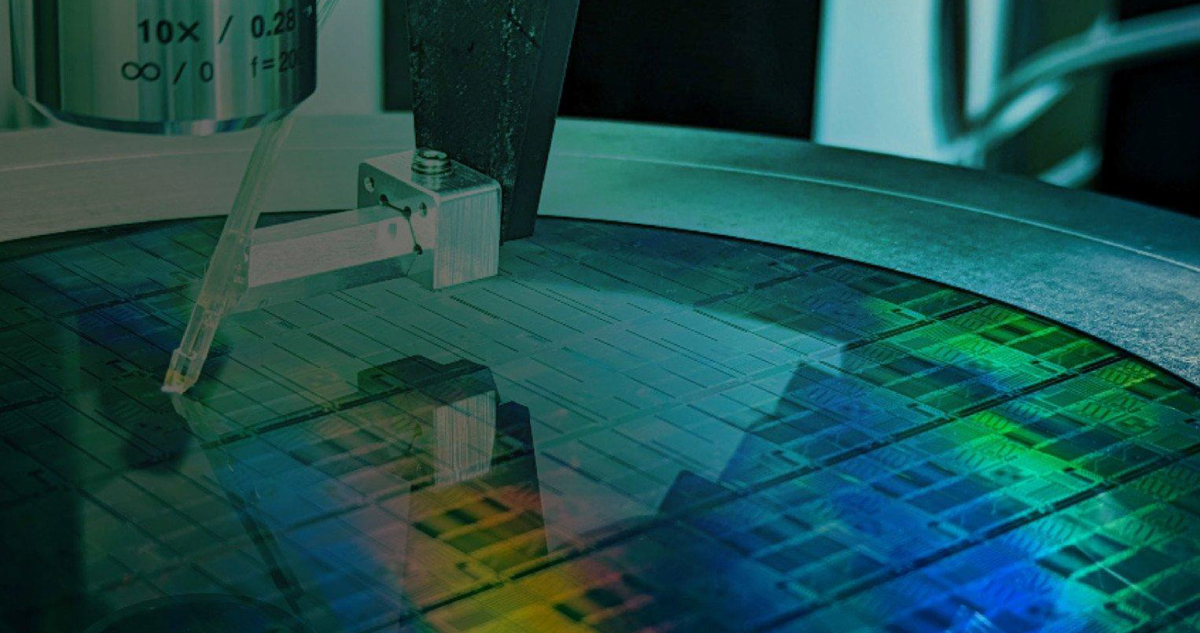

The fast maturing PIC die manufacturing has given rise to photonic wafers containing thousands of components made available by foundries through Process Design Kits (PDKs). Reliable testing is needed to optimise the different parameters of a given optical component.

Testing – The Challenges

- Accuracy/repeatability: Obtaining traceable results for tight acceptance thresholds and greater yield of known good dies.

- Dynamic range: Seeing full optical spectral contrast in a single measurement.

- Speed: Keeping alignment and measurement time to a minimum, but also accelerating the ease of the test and analysis iterative flow.

- From data to insight: Generating and managing structured data that is ready for artificial intelligence and business intelligence.

- Flexible/scalable: Leveraging test station modularity and third-party compatibility of software to improve test throughput and complexity over time or swap equipment as needed.

- Automation: Automating chip and wafer advanced navigation to control any instrument and execute data analysis in user-defined test routines to test massive circuits with minimal cost of ownership.

Testing PIC-based passive components is challenging due to the high port count of some components like Arrayed Waveguide Grating (AWG) and the huge number of components to test on a single die. A component test platform operates in conjunction with a continuously tunable laser to measure optical insertion loss, return loss and polarisation-dependent loss across the laser’s spectral range. Optical spectrum must be realised quickly and with a high wavelength resolution, typically to the order of a picometer.

Testing – The Process

The PIC devices are usually tested at the wafer level prior to dicing to detect defects as early as possible and to avoid packaging defective dies.

Using a PIC wafer probe station, light is coupled into the wafer to enable measurement of the optical characteristics of the DUT.

Testing Solutions for Photonics from MELSS

MELSS brings you Test and Measurement (T&M) hardware and software solutions from market leaders EXFO, which are automated, scalable, fast, accurate and cost-optimised. These T&M solutions range from those for Passive and Active components as well as automated probe stations for wafer and single-die testing.

The OPAL series of probe stations deliver industry-leading performance for testing wafers, multiple as well as single dies, enabling accurate, repeatable and fast measurement. The PILOT software suite offers automation capabilities that support the full test flow (preparation through measurement to results analysis), using EXFO’s or third-party T&M instruments.

EXFO’s comprehensive range of optical testing solutions includes component test platforms, optical testing solutions, light sources, benchtop tunable lasers, passive component testers, optical spectrum analysers, tunable filters with adjustable bandwidth, variable attenuators, switches and power meters.

EXFO has developed automated, scalable, fast, accurate and cost-effective Test and Measurement (T&M) hardware and software solutions. Ranging from simple optical testing to spectral optical characterisation or traffic analysis, EXFO offers an extensive selection of probe stations for wafer, bar, multi-die or single die configurations, and a powerful automation software suite.

The CTP10 from EXFO specifically addresses key PIC measurement challenges. measuring optical components quickly, reliably and accurately.

The CTP10 is a modular component test platform that operates together with the T200S or T500S continuously tunable lasers. The CTP10 characterises the spectral properties of high port count devices in one single scan with

- High spectral resolution

- 70-dB dynamic range, even at a sweep speed of 200 nm/s

- Operation from 1240 to 1680 nm

- Coverage of a wide range of applications, including telecom, sensing and LIDAR.

- Both optical and photocurrent measurements with analog output for PIC first-light search and coupling optimisation

- Fast data transfer

- Remote control using SCPI commands is possible

- Increased PIC testing throughput

- Reduced test time

- High sampling resolution of 20 fm

- Accurate measurement of narrow spectral features

The CT440 is a compact variant of the CTP10, with the same performance – ideal for the characterisation of PIC components with limited outputs.

In addition to the above range of products, EXFO produces other advanced products such as the T200S, T500S, CTP10, CT440, OSICS T100, FTBx-2850 and OSA20.