Does your Battery Test System use Regenerative DC Electronic Loads?

An electronic load complements a power supply when it comes to electronic testing. While a power supply tests electronic circuits under different sourcing conditions, an electronic load tests energy sources with static or dynamic loading.

Electronic loads are categorised into DC, AC, Regenerative DC, and Regenerative AC.

What is a DC Electronic Load?

A wide range of DC power sources, from DC power supplies and batteries to fuel cells and solar cells can be tested and characterised using DC electronic loads. Operating under various modes such as constant current (CC), constant voltage (CV), constant power (CW), and constant resistance (CR), DC electronic loads simulate power consumption under different load conditions, helping in the assessment of device energy efficiency under various operating scenarios.

DC power supplies such as battery chargers, converters, fuel cells, batteries, telecommunications rectifiers, etc must be tested for hundreds or thousands of cycles to determine factors like quality, longevity, durability, reliability, and expected lifetime.

Operating Modes

DC Electronic Loads work in many operating modes.

Constant Current (CC) mode

Here, the load’s power supply is a current source. At a constant current in the output terminals, the output voltage is varied with current load conditions.

Constant Resistance (CR) mode

Here, at a set resistance value, the load draws the current inversely to compensate for any change in the testing voltage.

Constant Voltage (CV) mode

At a fixed voltage. the electronic load sinks the current needed to keep the voltage constant.

Constant Power (CP) mode

For a constant wattage level during the test, the load draws the current proportionate to voltage change.

A well-designed DC programmable electronic load always controls the current, irrespective of the mode, allowing users to set a current level that the DC load will draw, regardless of any changes in voltage.

Regenerative DC Loads

Regenerative DC loads can simulate a wide range of load characteristics while also feeding energy back to the grid, providing an efficient and sustainable solution that reduces test environment temperatures, HVAC power consumption, and power conversion electricity costs.

Chroma 63700 Series Regenerative DC Electronic Loads

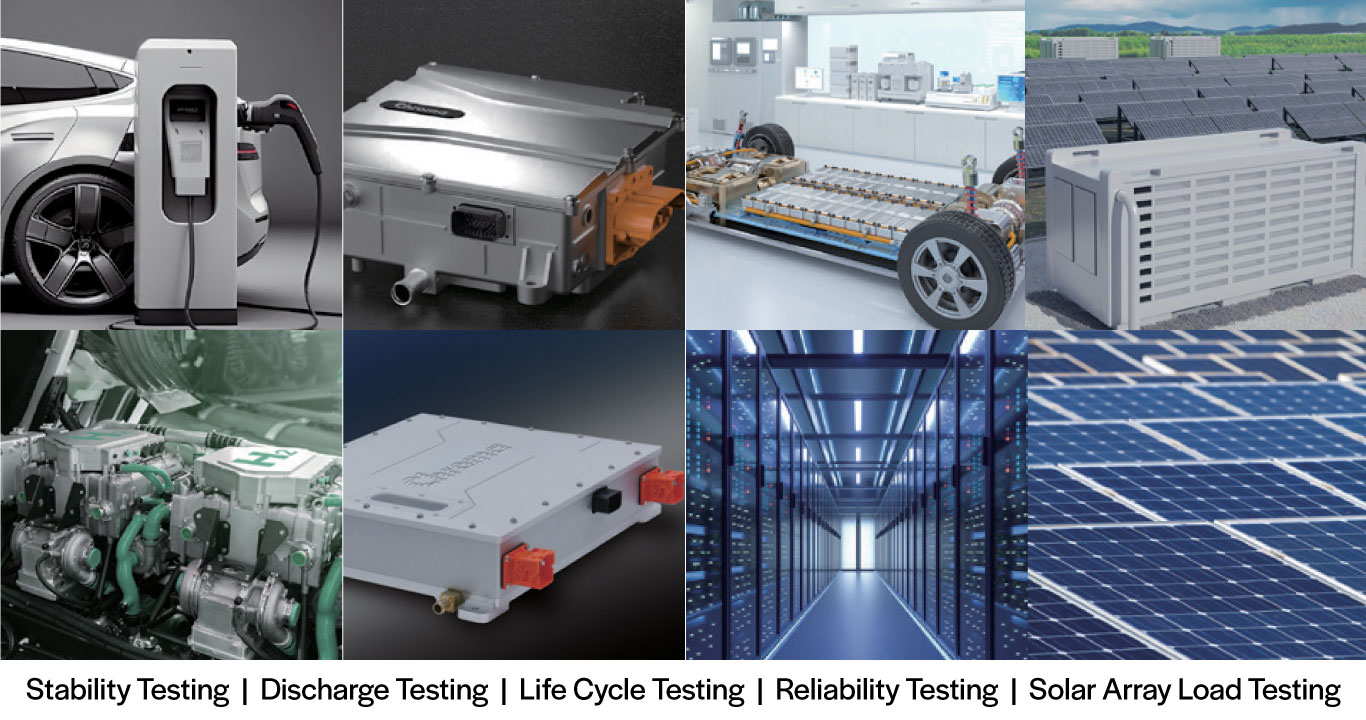

The Chroma 63700 Series Regenerative DC Electronic Loads are suitable for product reliability testing in a wide range of applications, such as electric vehicle (EV) battery discharge, fuel cell discharge, high-power power supply aging, DC EV supply equipment (EVSE), unidirectional on-board chargers (OBC), fuel cell systems, energy storage systems (ESS), AC/DC and DC/DC power supply burn-in tests, and various power electronics applications.

The 63700 Series offers high power density within a compact 3U form factor, with a power rating of up to 18kW per unit and currents of up to 540A. A maximum of 10 units in parallel provides a maximum power and current of 180kW and 1200A respectively. Voltage can be set at 100V, 600V, 1200V, or 1800V.

What’s more, the master/slave control enables parallel operation of identical 63700 units for synchronised dynamic loading to store up to 256 programmable sequences, thereby reducing test duration and increasing throughput during automated testing.

The external signal control functionality allows the simulation of real current waveforms. The 63700 Series performs precise voltage and current measurements in real-time. Operation and setup are convenient with the TFT touch display and rotary knob on the front panel, with the capability to control via LAN, USB, GPIB, or CAN.

The 63700 Series is an ideal solution for design verification and integration into automated test systems with its over-current, over-power, and over-temperature protection functions, as well as an over-voltage alarm mechanism, ensuring product reliability during testing.

MELSS provides Battery Test System solutions using the latest in DC Electronic Loads such as the 63700 Series from Chroma.