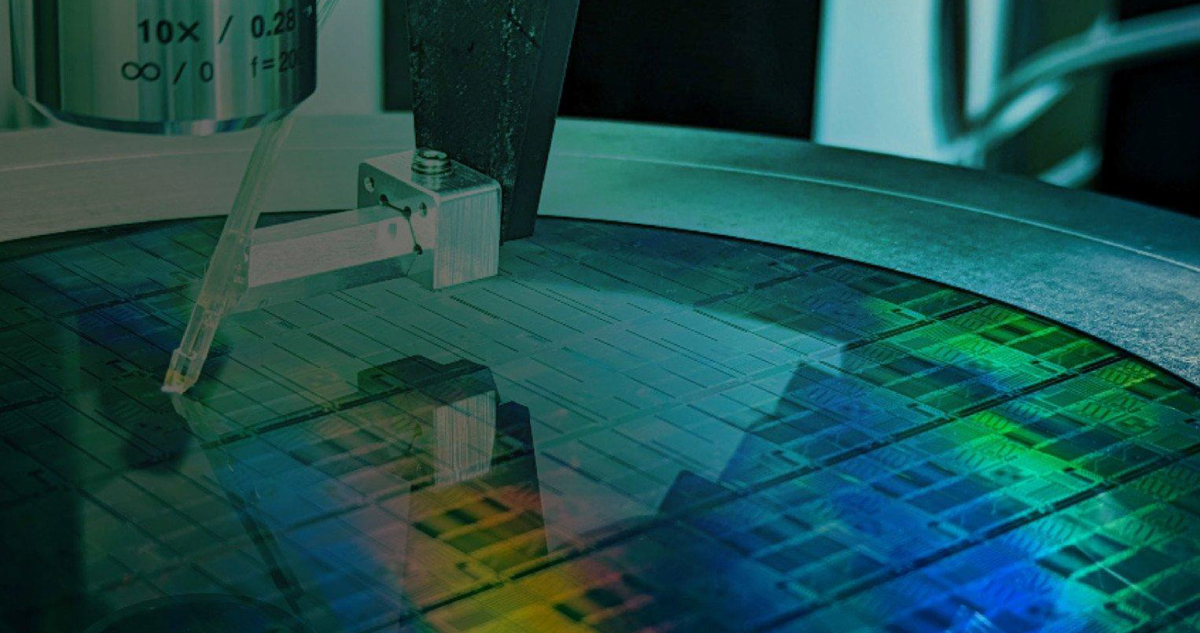

For unmatched volume production and zero-compromise quality in semiconductor devices, choose Handlers and Testers from Cohu®

Semiconductor devices have pervaded industries and human needs today. From System on Chip (SoC) and Micro-Electro-Mechanical System (MEMS) to Printed Circuit Board (PCB), the exhaustive range of device types calls for more functionality even with smaller form factors. Volume production of zero-defect devices is required to handle the increasing demand. Enhanced speed of test is paramount while testing a semiconductor device.

To meet this demand, MELSS brings you Handling and Testing solutions from Cohu® – the technology leader in test, automation, inspection and metrology products and services for the semiconductor industry.

Cohu’s product portfolio includes a wide range of pick and place, thermal and gravity test handlers for MEMS, sensor and turret test and scan applications, a broad spectrum of interface solutions for automotive and power, 5G wireless, artificial intelligence, and data processing applications. Also including probes and contactors, it enables optimised yield and productivity, and accelerates customers’ manufacturing time-to-market.

Gravity Test Handlers

Capable of handling extremely small to very large packages, over a very wide temperature range, they are ideal for high throughput octal site and quad site testing.

Cohu is the market leader in gravity test handlers with an installed base of 6,000 gravity systems today.

Turret Test and Scan

Turret Handlers are high-speed, high-accuracy devices that handle, inspect and test semiconductor components.

Turret platforms from Cohu for semiconductor testing, inspection and packaging provide:

- Highest Throughput for Fragile Devices

- Highest Processes Integration Capabilities

- Flexible Test and Scan Solution for FFC Devices

- Market Leading Inspection Yield with high Throughput

Pick-and-Place Test Handlers

Cohu pick-and-place test handlers automate the movement of semiconductor devices, control temperature during testing, and offer vision inspection capabilities to ensure quality and optimise yield in volume production, with models like the Delta MATRiX, Delta Eclipse, and MT9510 XP/x16.

Features such as automated movement of semiconductor devices such as ICs – from input to test sockets and then to output – ensure efficient and reliable handling.

These handlers provide high-speed testing. While the Delta Eclipse is capable of testing up to 16 ICs in parallel and achieving throughputs of up to 12,000 UPH, the MATRiX handler’s highly flexible test site configuration makes it suitable for a wide range of test applications.

Many Cohu handlers, such as the MT9510 XP/x16, offer tri-temperature control, allowing for testing in cold, hot, or ambient conditions.

The MATRiX handler incorporates Cohu’s T-Core active thermal control (ATC) technology, which dynamically removes heat from devices during testing, minimising test time and yield loss.

The MT9510 XP/x16 test handler provides full temperature control during testing in extreme environmental conditions from -55°C to +175°C.

Cohu offers a broad range of IC pick-and-place test handling solutions with thermal, vision and factory 4.0 automation options for the automotive, mobile, and computing markets.

Cohu’s NV-Core inspection system also provides advanced inspection capabilities such as 3D topographic inspection, sidewall micro-crack detection, and infrared inspection for sub-surface defect detection.

Devices are inspected for dimensional or cosmetic defects, lead irregularities, pad bridging, or contamination. The vision system can verify the expected presence/absence of components on input/output units, inside sockets, and on pickups to prevent jams.

It also scans all devices in input, identifying each DUT by 2D code reading and storing the data in the handler database for MES integration.

MEMS and Sensor Test

MEMS are micro-scale systems that integrate mechanical components (like sensors, actuators, and micro-structures) with electronic circuits on a single chip.

These are capable of integrating not only complex functions in very small devices, but also capable of integration with other semiconductor components, leading to smaller, more efficient, and more powerful systems. To be capable of performing a wide range of functions such as sensing (e.g., acceleration, pressure, temperature), actuation (e.g., controlling fluids, moving parts), and microfluidics, their handling and testing is crucial.

Cohu MEMS solutions combine the advantages of well-established and production-proven tri-temp test handling equipment with innovative concepts to meet the special requirements of the MEMS market.

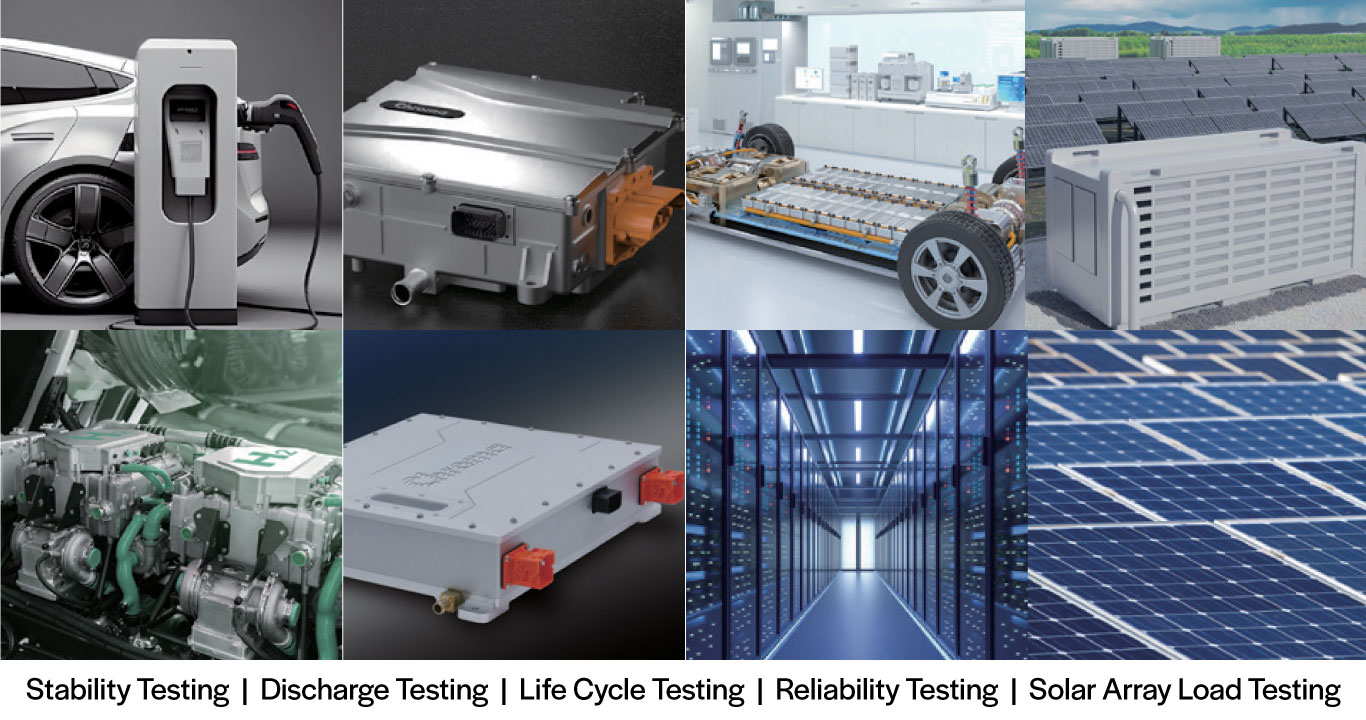

Interface Solutions

To complement the aforementioned solutions, Cohu also offers the requisite interface solutions for many industries:

- Automotive and power

- Artificial intelligence

- Virtual and augmented reality

- 5G infrastructure

- Cloud computing

- Wearables and Internet of Things

- Sensors and actuators

- Radio Frequency devices

Cohu is the only company with expertise in the entire test cell and inspection needs of the semiconductor manufacturing industry.

The exhaustive range of solutions from Cohu is brought to you by MELSS as part of its solutions for the semiconductor manufacturing industry.

For more information, please visit: