End of Line Testing

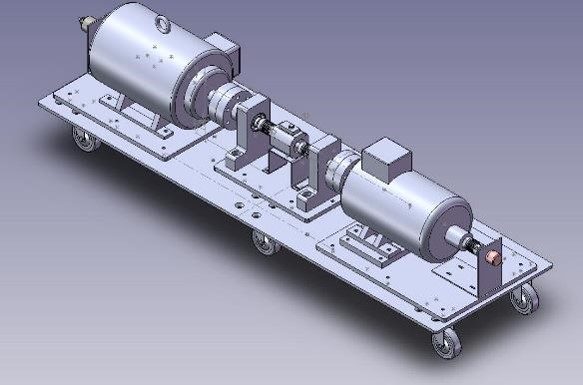

MELSS End of Line (EOL) Test Solutions

We provide advanced and adaptable EOL testing systems tailored to diverse industry needs:

- Electronic, Vision, Electro-mechanical & Robotic Systems

- Functional Testing – Ensures the product performs as intended under real-world conditions.

- Dimensional Testing – Validates physical measurements and tolerances.

- Quality Testing – Identifies any cosmetic or material defects.

- Endurance Testing – Assesses product durability under prolonged usage.

- Customized & Modular Solutions – Scalable to align with customer production volumes and evolving requirements

Expertise in End-of-Line Testing Solutions

With over 30 years of industry experience, MELSS is a trusted provider of End-of-Line (EOL) Testing solutions for a wide range of sectors, including Electronics Manufacturing Services (EMS), Automotive, Telecom, Aerospace, and Defence. Our deep understanding of manufacturing workflows ensures reliable, high-performance testing systems tailored to customer needs.

Our PCC-based test solutions integrate cutting-edge data acquisition, real-time analysis, and intuitive user interface design, backed by over a decade of software development expertise.