Industry 5.0 for a balanced approach to your automation needs

The vision for the Fourth Industrial Revolution – or Industry 4.0 – was presented at the Hannover Messe fair in Germany in 2011.

The term Industry 5.0 was borne out of the Japanese invention – Society 5.0 at the CeBIT 2017 trade fair in Hannover, Germany.

While Industry 4.0 was embraced by industry with a lot of fanfare, continued practice revealed its shortcomings too, leading to the adoption of an industrial revolution with a more humane approach – Industry 5.0.

Common factors of both Industry 4.0 and Industry 5.0

Industry 5.0 builds on the basic tenets of Industry 4.0 with its inherent benefits at the business level.

- While big companies implement robotic solutions and fully automated industrial machines across large manufacturing and logistics facilities, smaller medium-sized businesses utilise robotics in the form of collaborative robots (Cobots) which are smaller, more affordable, and easier-to-use industrial devices.

- Robotics, smart machines and automation solutions have not only replaced human workers to perform repetitive, mundane and dangerous tasks, they do so more efficiently with more consistent product quality and production line flows, allowing companies to manufacture high-quality products at lower costs.

- Interconnected industrial automation systems, IoT devices and robots consistently generate large volumes of data about the work processes, manufacturing and production line flows, providing vital business insights for further optimisation of industrial environments and manufacturing processes. The data is also used to create more flexible robots and smart manufacturing solutions to enable manufacture of a wider range of consumer products. This flexibility is to cater to customers demanding preconfigured options with minimum manufacturing costs.

- Automation and robotic solutions can be implemented anywhere in the world, making it easier to relocate many manufacturing jobs to countries with low-cost labour.

Limitations of Industry 4.0

1. Well-being of workers and social dimension

Industry 4.0 led to improved efficiency, precision and productivity, leaving the social dimension of the new industrial revolution completely out of scope.

2. Economic resilience and regenerative features

The designs of robotic and AI-controlled production lines lacked the vision for restorative feedback across all the operational processes and layers.

3. Environmental aspect and promotion of green energy adoption

Although Industry 4.0 was also centered around energy efficiency and total optimisation of operational processes, it viewed energy consumption and resources utilisation from the business performance perspective alone.

4. One-sided perception of the role of robotics and automation solutions

Machines, technologies and devices designed to complement human capabilities played a secondary and supportive role in production lines with Robotics playing the major role in Industry 4.0; led to Industry 5.0.

Although automation and robotics have created a new benchmark for higher quality, efficiency and productivity which is difficult to emulate by the human workforce, they have led companies to focus more on revenue generation, often ignoring environmental impact. In many ways, this led to the concept of Industry 5.0 starting to gain momentum.

Industry 5.0 can be seen as a revised version of Industry 4.0 after addressing its shortcomings; many features are common to both.

How does Industry 5.0 differ from Industry 4.0?

In the Industry 5.0 vision, robots, smart machines, IoT, AI and Big Data are still the key to business success, but emphasis on increasingly intelligent and efficient devices is balanced with more focus on sustainability, resilience and enhancement of human talent.

Industry 5.0 adds the human touch to Industry 4.0 by focusing more on machines and new technologies for better empowerment of human workers.

Here are some of the most common human-machine-interaction technologies used in Industry 5.0:

- Collaborative robots working alongside human workers

- Virtual reality (VR) and augmented reality (AR) for industrial testing, personnel training and inclusiveness

- Advanced working instruments and safety equipment, enhancing human capabilities with robotic tools and data connectivity

- Automatic recognition of human speech and gestures

- Augmenting cognitive abilities of human workers with AI and other innovative tech

- Tracking devices to monitor health and mental state of human workers

- Recyclable and recycled (generated from waste) materials

- Raw, living, self-repairing and lightweight materials

- Materials with intrinsic traceability

- Artificial intelligence (AI)

- Energy-autonomous biosensors

- Energy-efficient data transmission and analysis

Industry 5.0 vision

Industry 5.0 is envisioned as:

- Integrating human workers and machines in industrial environments

- Instead of robotic solutions and smart machines replacing humans they now support and augment human work

- Repositioning human workers from repetitive tasks to more creative jobs that require problem-solving, experience and intuition

- Moving away from excessive automation

- Moving towards a more balanced approach with optimal use of robotics

- Focusing more on customer experience

- Building responsive and distributed supply chains

- Designing and manufacturing not only customised but also interactive products

- Addressing the security risks and vulnerabilities of interconnected industrial automation systems

Frost & Sullivan had envisioned bringing back empowered humans to the shop floor, at the SPS fair in 2019.

Elon Musk had shared the drawbacks of too much reliance on automation and summarised in his tweet thus: “Yes, excessive automation at Tesla was a mistake. To be precise, my mistake. Humans are underrated.”

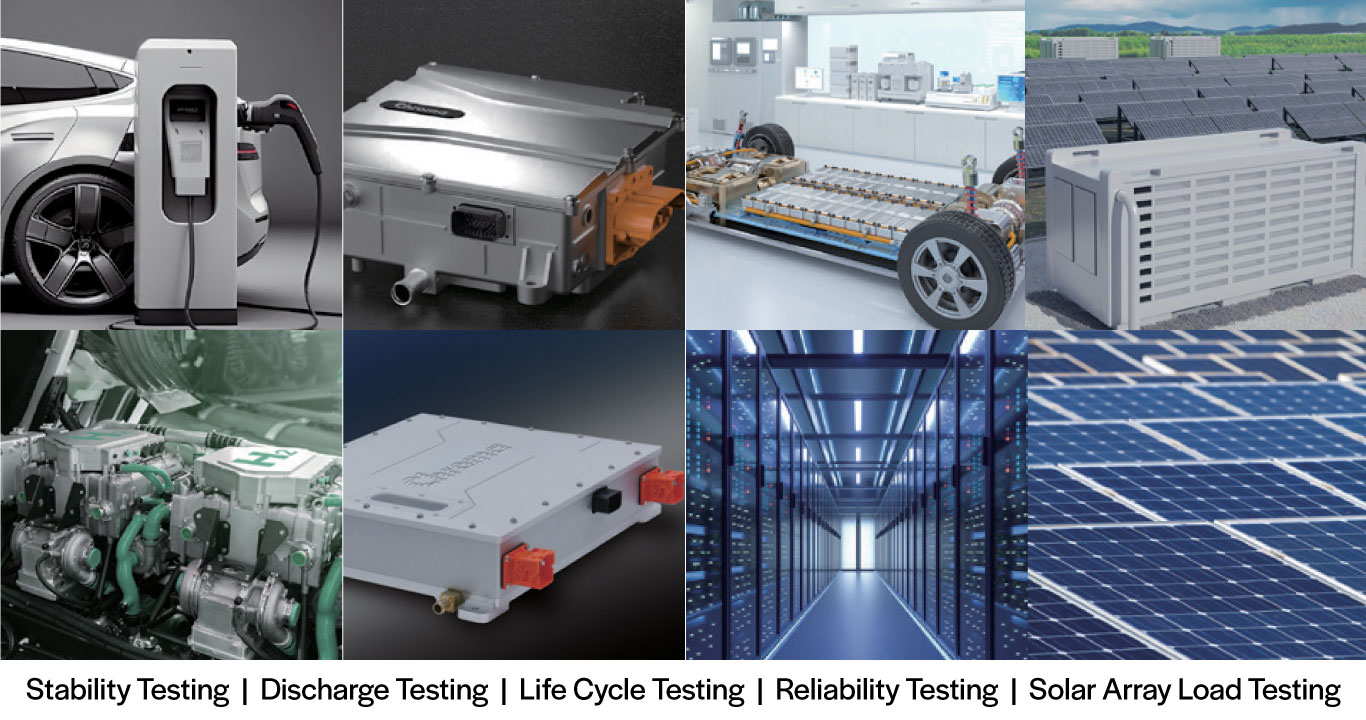

MELSS provides a wide range of products and services for the implementation of Industry 5.0 such as the Sixdime range of IoT products, and in Industrial automation and robotics.

Please give us a call and our professionals will reach out to you to study your requirements and will provide solutions not only to help you with Industry 5.0 needs, but any other industrial needs too.