Is your Manufacturing Unit ready for the Future?

Emerging technologies have been the driving force of each industrial revolution. Currently, manufacturing is driven by the technologies of the fourth industrial revolution (Industry 4.0).

The current manufacturing scenario in Industry 4.0 is marked by the increasing use of digital technology, artificial intelligence, quantum computing, nanotechnology, biotechnology, renewable energy, and the internet of things, where automation and intelligent machines are revolutionising production processes, increasing efficiency, and driving innovation, using information from the vast pools of data generated from each physical equipment on the shop floor.

Many emerging technologies are driving today’s manufacturing sector:

Additive Manufacturing

Additive Manufacturing (AM) or 3D Printing is a game changer in manufacturing. It replaces the existing manufacturing process which is synonymous with generation of material scrap or wastage.

As the name suggests, Additive Manufacturing starts with the end product design being drawn out using advanced CAD. The end product is created by adding one layer of the design over the other, layer by layer until the final functional product is shaped, using appropriate materials in each layer. No wastage is generated.

In addition to reduced wastage, AM also helps in on-demand manufacturing, reducing the need to stock the end product, thereby resulting in a more efficient supply chain.

Augmented Reality and Virtual Reality

Augmented Reality is used to improve the manufacturing process by identifying errors and reducing faults. The operator controls his manufacturing environment in real time by quickly making changes based on the findings using AR. Virtual Reality tools are purely virtual and manufacturing follows the VR models.

Industrial Internet of Things (IIoT)

In an IIoT system, Programmable Logic Controllers (PLCs), Industrial Control System (ICS), and Supervisory Control and Data Acquisition (SCADA) systems receive data from ambient as well as equipment sensors and provide actionable insights into physical events and the environment within a factory, such as equipment performance or early warning alerts about the environment. The data is processed either using IoT edge devices or on the cloud for further action.

The physical infrastructure, communications, data, devices, and security in a factory are governed by protocols and standards to enable Machine to Machine (M2M) and human communications.

Digital Twins

A Digital Twin is a virtual representation of a physical system or object that is created using data from any existing physical system to visualise it under varying conditions and improve its performance by applying the virtual replica, thus visualised, to the physical system. This helps to increase productivity.

Artificial Intelligence (AI) and Machine Learning (ML)

Artificial intelligence and Machine Learning are helping to replace the traditional rule-based industrial automation with adaptive automation which is capable of reacting to unforeseen scenarios and making complex decisions without human interference.

Big Data

Industry 4.0 would not be possible without the availability of vast pools of historical and real-time data from the sensor-enabled IoT equipment and devices used in the manufacturing industry, also known as Big Data.

Edge Computing

The data can now be processed near the source of data generation using edge devices – enabling availability of meaningful information in real time for quicker decision-making.

Regenerative Energy

Energy conservation through energy regeneration is another technological advance that is not only helping make our planet more sustainable but is also helping to reduce the costs of goods produced in the manufacturing industry by reducing its expense on energy.

Industrial Automation and Robotics

Although robotics has been around since 1950, its widespread use across the manufacturing sector is still a work in progress, and rapid strides are continuing to be made with the availability of the more affordable robots – Cobots. Robotics, along with other modes of automation, has been revolutionising the manufacturing industry by improving quality and increasing production.

Biomanufacturing

Biomanufacturing is a trend that is fast catching up with the manufacturing industry, wherein biologically activated materials are used as raw materials. It has found use in many industries including food processing where the shelf life of food is increased, pharmaceuticals where medicines and vaccines are created, consumer products manufacturing such as beauty supplies, plastic products and components, nylon, textiles, and paper. Even electronic product manufacturing benefits from flexible PCBs created by biomanufacturing.

Advanced Materials

Research in Material Science is an ongoing process which has been helping manufacturing by inventing advanced materials with unique properties and characteristics which improve performance, reduce weight, enhance durability, and increase efficiency.

Advanced materials are helping in the manufacture of advanced versions of a wide range of equipment, from home appliances to electric vehicles and spacecraft.

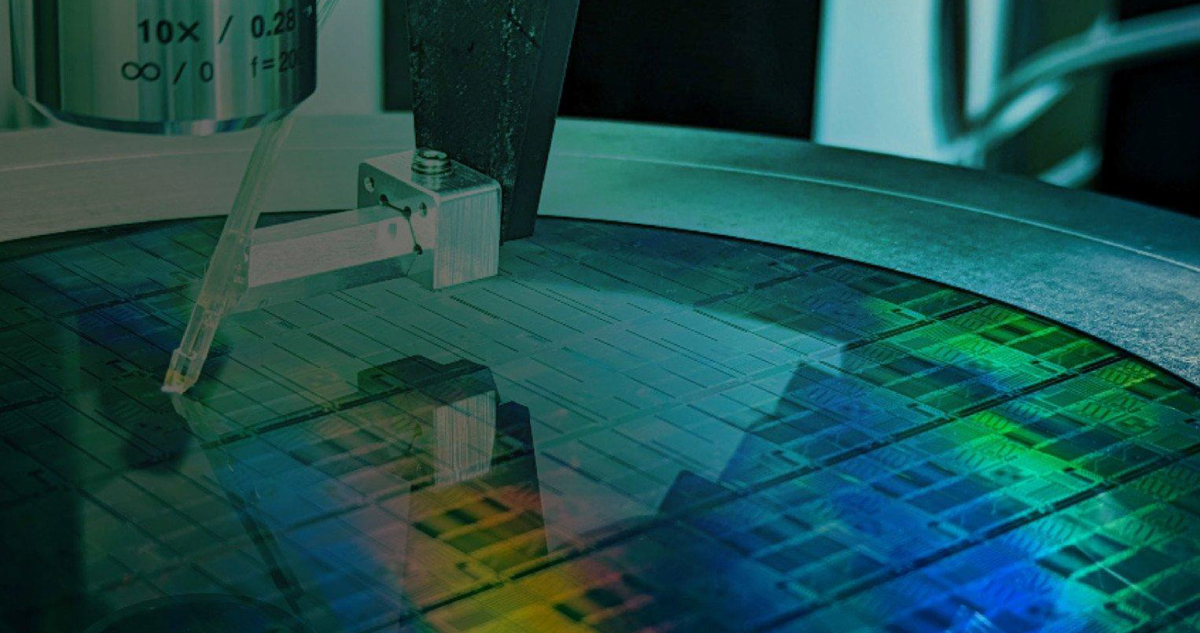

Photonics

The Internet and Communication industries have gained from the use of photonics which has increased the speed of communication over longer distances. Photonics is increasingly replacing electronics wherever possible

Blockchain Technology

Although more often associated with cryptocurrency and financial transactions, blockchain technology is increasingly being used in manufacturing. It helps in end-to-end traceability from raw materials to finished goods and brings in maximum transparency to the manufacturing process by updating information in a block at each stage of manufacturing. After each stage of updation, the information cannot be changed, making the process very secure. This helps in quick identification of any fault, and the where and how of it – leading to quicker recovery from faults.

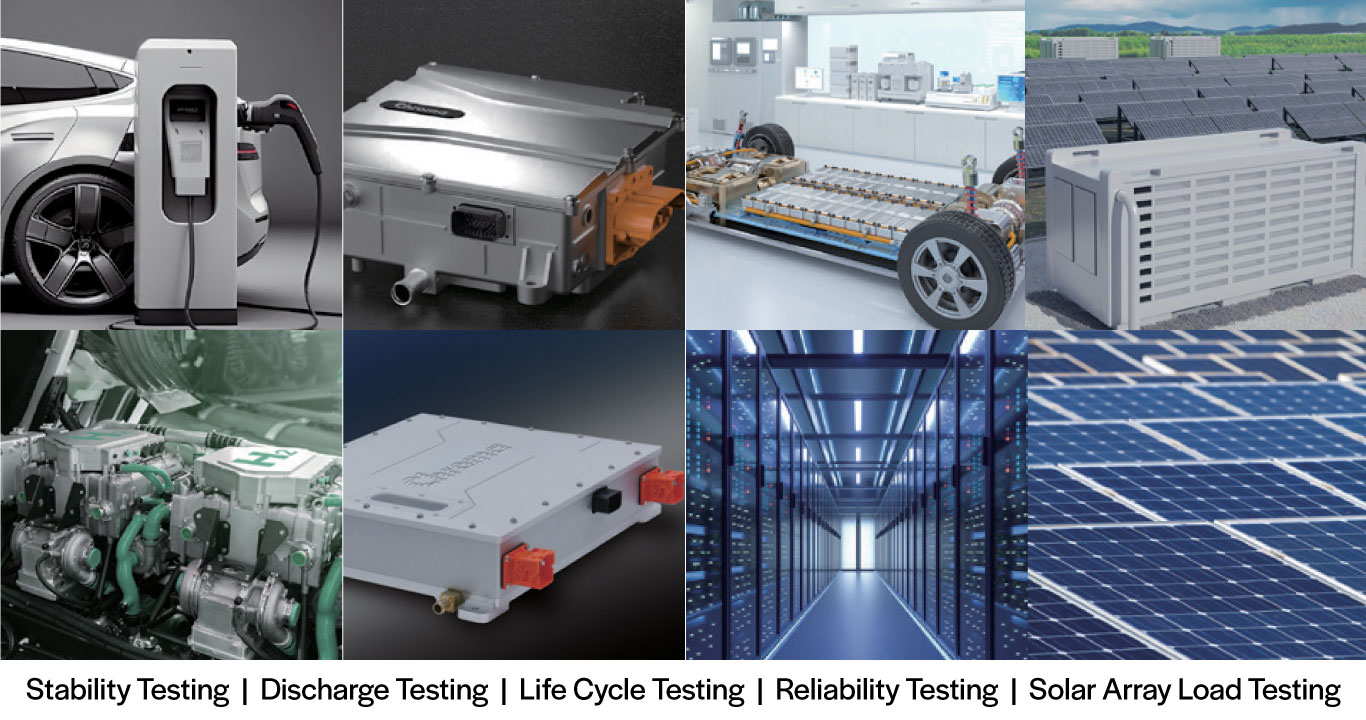

MELSS has been helping industry with many solutions using emerging technologies such as Industrial Automation and Robotics, Collaborative Robots, Electric Vehicle Test Solutions, End of Arm Tooling, Battery Test System, and in Telecom & Photonics and Industry 4.0.