Sixdime Data Logger

Sixdime Data loggers perform the unique role of data acquisition from different sources such as sensors and PLCs to generate information in real time which helps decision-making.

MELSS presents the Sixdime Atom IoT Data Logger for true real-time and data-driven monitoring and control of devices and equipment such as PLC, HMI, Motors, Valves, Energy Meters, Actuators and Relays. Compatible with networking protocols such as 4G/LTE, Wi-Fi, MODBUS and NB IoT, it helps in traceability, improvement of OEE and employee resource mapping.

The application generates various shift-wise and machine-wise productivity and analytics reports such as for loss, productivity and WIP monitoring which can be processed at the edge devices or on the cloud for real-time monitoring and decision-making.

Sixdime Data Logger application was developed with the aim of providing a comprehensive solution for acquisition and mapping of the following key operational indicators:

- Traceability from Raw Materials (RM) to Finished Goods(FG)

- Stage wise Waste Analysis – Input Vs Output Comparison

- Machine Parameters

- Employee resource mapping to work centres, monitoring and control

At the same time, due importance was given to the human perspective as well – Operator Information and Operator Availability.

The Sixdime Data Logger, comprising a comprehensive Manufacturing Execution System (MES) and a Traceability Engine, covers every stage of the manufacturing process.

Barcode Printers are used to generate a barcode labels which would provide the unique identity to all RMs. Barcode scanners are used to read the barcode labels to facilitate tracking. RFID tags are also used for certain Incoming materials, and subsequently at each stage of the process.

RFID tags are read using RFID based Android Tablets and the data is transferred to PC for processing and establishing Traceability. At each stage waste analysis is performed and Output vs Input is compared. At each stage depending on the requirement, a HMI is provided to key in and monitor the set and process parameters respectively. Weighing system at certain stages is required to weigh the output material as part of the quality requirement.

The data acquired from hardware at each stage is interfaced with the PC which is equipped with the Traceability Engine to provide Tracking, Traceability functions and Productivity Reports & Analytics.

Download Catalogue

Download CatalogueBenefits

- Wastage / Loss Analysis/Productivity

- Shift / Machine wise Productivity analysis

- RM to Finished goods traceability

- Real time Work In Progress (WIP) Monitoring

- Time series data logging of machine parameters

- Handheld tabs can be provided upon request for mobile monitoring

- Tracking

- Material Accountability

Key Features for Sixdime Data Logger:

- Easy to setup and configure

- Can send warnings by Email/SMS

- Quick solution for real-time reporting

- Supports Recording And Storage Of Data.

- Playback Function To View Historical Data Based On Time/Event.

- Data Monitoring / Quality Reports.

- Alarm / Downtime Reports.

- Equipment Preventive Maintenance Reports.

- Can Sustain Robust Data Acquisition And Storage.

Why Sixdime Datalogger?

- Easy-to-setup and configure

- Provided as Cheaper Solution, as no one has to be paid to take the readings

- Playback function to view historical data

- Quick Solution for Real time Reporting

- Readings are accurate because no human errors are introduced

- Have capability to collect readings automatically using sensors

- Can be used in hazardous environments even where it is difficult for human interference

- Data is processed Faster

- Supports Data to be stored on the Database for further analysis on any platform

- Readings can be taken at exactly the right time

- No missed readings because they are taken automatically

- Scalable system where traceability and tracking can be implemented for example even at supplier end

What are Data Loggers?

Data loggers are electronic devices which automatically monitor and record environmental parameters over time, allowing conditions to be measured, documented, analysed and validated.

The data logger contains a sensor to receive the information and a computer chip to store it. The information stored in the data logger is then transferred to a computer for analysis.

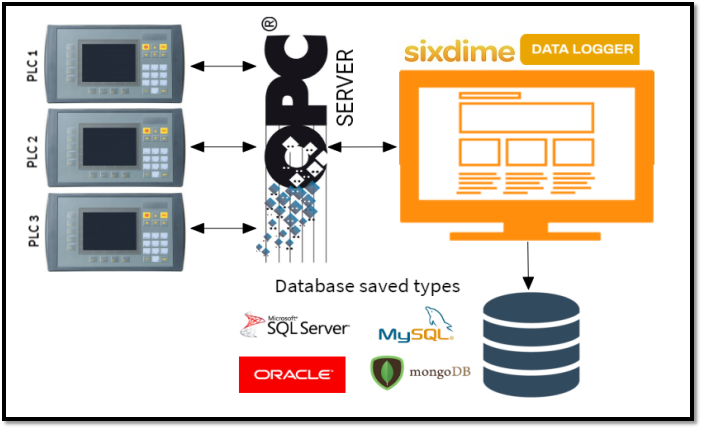

What is an OPC Server & PLC?

OPC Server: The OPC (Open Platform Communication) is a software interface standard that allows windows programs to communicate with industrial hardware devices.

OPC is implemented in server/client pairs. The OPC server is a software program that converts the hardware communication protocol used by a PLC into the OPC protocol. The OPC client software is any program that needs to connect to the hardware, such as an HMI. The OPC client uses the OPC server to get data from or send commands to the hardware.

PLC: A PROGRAMMABLE LOGIC CONTROLLER (PLC) is an industrial computer control system that continuously monitors the state of input devices and makes decisions based upon a custom program to control the state of output devices.

Almost any production line, machine function, or process can be greatly enhanced using this type of control system. However, the biggest benefit in using a PLC is the ability to change and replicate the operation or process while collecting and communicating vital information.

Do you want to improve your manufacturing process?

We are an IT product and service provider with a focus on delivering highly scalable solutions for factories and industries. Reach out to us and find out know how we can make your manufacturing process more efficient.