MELSS in partnership with OnRobot A/S offers End-of-Arm-Tools (EOAT) and End Effectors for industrial and collaborative robots (COBOTS) in India.

RG2 Gripper:

The RG2 – 2kg payload robot arm gripper is a flexible collaborative gripper with built-in Quick Changer up to 110mm stroke. It provides intelligence, fast deployment, easy customization and programming. The outstanding software features through our one system solution decreasing engineering and manufacturing time significantly. The RG2 gripper is a tool for a wide range of applications. Customized fingertips provide great gripping flexibility, customers can use one tool for different parts of the production process maximizing robot utilization. The RG2 works seamlessly with our Dual Quick Changer and any of our other grippers to help you maximize utilization of your robots. RG2 is TÜV certified, comes standard with safety shields.

RG2 – FLEXIBLE 2 FINGER ROBOT GRIPPER WITH WIDE STROKE:

- Flexible grippers can be used for a wide range of part sizes and shapes.

- Plug-and-produce design reduces deployment time from a day to an hour.

- Easy deployment with out-of-the box grippers reduces programming time by 70%.

RG6 Gripper:

The RG6 – 6kg payload robot arm gripper is a flexible collaborative gripper with a built–in Quick Changer, up to 150mm stroke. It provides intelligence, fast deployment, easy customization and programming. The outstanding software features that come with the product enable intelligent applications. The RG6 gripper is a tool for a wide range of applications. Customized fingertips provide extensive gripping flexibility, customers can use one tool for different parts of the production process maximizing robot utilization. The RG6 works seamlessly with our Dual Quick Changer and any of our other grippers to help you maximize utilization of your robots. RG6 is TÜV certified, comes standard with safety shields.

RG6 – FLEXIBLE 2 FINGER ROBOT GRIPPER WITH WIDE STROKE:

- Flexible grippers can be used for a wide range of part sizes and shapes

- Plug-and-produce design reduces deployment time from a day to an hour

- Easy deployment with out-of-the box grippers reduces programming time by 70%

RG2-FT Gripper:

The RG2-FT is a state-of-the-art gripper with added sensing and intelligence. It has a built-in force/torque and proximity sensor providing very precise automation. This enables true collaboration with human operators, supporting them like a co-worker would. Insertion processes can be achieved faster and more precisely. This gripper can easily insert pins for instance, where humans would struggle. Due to advanced sensor technology, during assembly the gripper gives the robot the ability to feel when the part has been mounted correctly. RG2-FT offers high productivity, fast deployment saving engineering hours on integration.

RG2-FT – SMART ROBOT GRIPPER WITH IN-BUILT FORCE/TORQUE AND PROXIMITY SENSOR

- Accurate sensing improves production quality by reducing defect rates as much as 60% in delicate pick-and-place processes

- Easy-to-program sensing allows robots to act like an operator’s third arm, with human-like part hand-offs.

- Ability to automate insertion tasks that weren’t previously possible, reducing operation costs by 40%

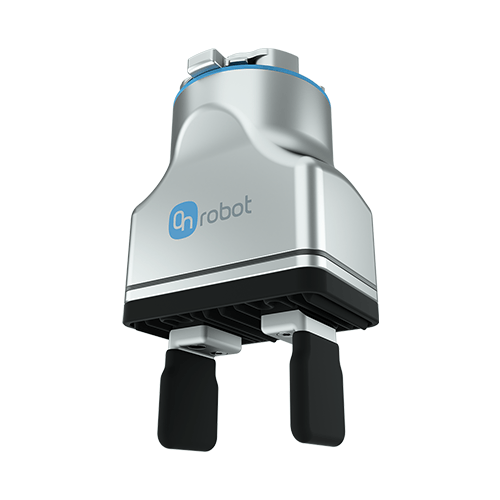

2FG7 Parallel Gripper:

OnRobot’s 2FG7 is a complete, low-cost, off-the-shelf electric parallel gripper that can be deployed within minutes and requires no custom engineering for installation, programming, or maintenance. The 2FG7 is easily redeployed on any major collaborative or light industrial robot, making it ideal for low-volume, high-mix production, and enabling fast ROI for many different applications.

2FG7 – NO-FUSS PARALLEL GRIPPER FOR TIGHT SPACES AND DEMANDING PAYLOADS

- Complete, easy-to-program, collaborative parallel gripper gets to work fast in a wide range of applications

- Strong parallel gripper is easy to deploy in tight spaces and handles demanding payload requirements

- Get fast ROI with a single flexible, intelligent, and precise gripper that can be easily customized and adapted for many tasks

- Ready for use almost anywhere, with IP67 rating for harsh environments and ISO Class 5 certification for clean room use

MG10-Magnetic Gripper:

OnRobot’s MG10 is a versatile, easy to use magnetic gripper for material handling, assembly and machine tending applications in manufacturing, automotive and aerospace environments. Fully compatible with all major robot brands through OnRobot’s One System Solution, the MG10 offers unique adjustable force and grip detection features that provide users with unprecedented levels of control.

VERSATILE ELECTRIC MAGNETIC GRIPPER FOR SAFE AND PRECISE COLLABORATIVE APPLICATIONS

- Electric magnetic gripper offers fast out-of-the-box deployment without the complexity and costs of external air supply

- Built-in intelligence with easily adjustable force and part detection ensures reliable handling of a wide range of part sizes and weights

- Fast, compact and customizable gripper to fit all your application needs

- Ensure safe and reliable operation by maintaining grip even after power loss or emergency stop

3FG15 three-finger gripper

FLEXIBLE, LARGE-STROKE 3-FINGER GRIPPER

- Flexible production – large-stroke optimizes CNC lathe-tending for multiple part sizes with a single 3-finger gripper

- Accurate centric positioning drives higher quality, consistency, and output with minimal programming

- Strong, stable grip with 3 contact points makes gripper fast and easy to redeploy for multiple processes

- Accomplish more with customizable fingertips to flexibly grip a wide range of part sizes and shapes

Why 3FG15 three-finger gripper?

The 3FG15 is ideal for gripping a wide range of cylindrical objects in machine-tending applications such as CNC lathe machines. The gripper’s design automatically centers work pieces, resulting in fast deployment with a strong, stable grip and precise placement. With a payload of up to 15kg, the 3FG15 competes with larger, bulkier, and much less flexible finger grippers. Like all On Robot grippers, 3FG15 offers seamless integration with the robots of your choice.

VG10 Electric Vacuum Gripper

VG10 – FLEXIBLE, ADJUSTABLE ELECTRICAL VACUUM GRIPPER

- Out-of-the-box deployment—plug into the robot arm and configure the gripper to fit the product—provides fast productivity and ROI.

- No external air supply required reduces maintenance costs and speeds deployment.

- Dual gripping functionality enables shorter cycle time.

Why VG10 Electric Vacuum Gripper?

Since the VG10 doesn’t require a compressor or air supply, it’s compact and easy to move around, bringing flexibility to your production line and saving maintenance cost. It has flexible arms and adjustable vacuum enabling the VG10 to handle a variety of objects in many different sizes. It’s a dual gripper – you can control the right and left sides of the vacuum gripper independently of one another, further increasing efficiency on your production line.

Seamless integration with the robot of your choice. The gripper comes with dual grip functionality, tool changer and a variety of typical vacuum cups. Additionally, there are many third-party vacuum cups available on the market to fit every application.

2FGP20 -VERSATILE ELECTRIC GRIPPER:

The OnRobot 2FGP20 electric gripper offers a wide stroke and customizable arms to easily handle heavy or open boxes, shelf-ready products, and other containers such as Euro containers (plastic KLT bins) that can’t be handled with traditional vacuum grippers. Like all OnRobot electric grippers, the FGP20 provides fast, out-of-the-box deployment with intuitive programming. An integrated vacuum gripper places slip sheets without changing the gripper or requiring another handling method. The 2FGP20 gripper has a versatile payload of 9kg (including gripper), making it ideal for handling food boxes or pouches and tetra-packed items, as well as fast-moving consumer goods such as toiletries, cosmetics, and pharmaceutical products.

VERSATILE ELECTRIC GRIPPER FOR PALLETIZING AND SLIP SHEET HANDLING

- Highly versatile palletizing gripper with wide stroke and customizable arms handles heavy or open boxes, shelf-ready products and other containers that can’t be gripped with vacuum

- Integrated vacuum gripper handles slip sheets without changing the gripper or requiring other handling method

- Off-the-shelf gripper saves significant engineering effort and shortens deployment time

- Electric gripper offers fast out-of-the-box deployment without the complexity and costs of external air supply

Gecko Single Pad Gripper

COMPACT NO-MARK GECKO SINGLE PAD ADHESIVE GRIPPER

- Compact, lightweight Gecko Single Pad Gripper requires no cables, electricity, air, or programming for cost-effective, plug-and-play performance

- Innovative adhesive gripper for flat, smooth, or perforated objects automate tasks that were previously not possible

- No-mark gripping even for shiny surfaces – cleaning step is not required, saving time and improving productivity

Why Gecko Single Pad Gripper?

The Gecko Single Pad (SP) Gripper brings the innovative Gecko adhesive gripper technology to small-footprint applications that were previously impossible to automate. The gecko-inspired adhesive technology offers precise, no-mark gripping, even for perforated items such as circuit boards or for shiny surfaces, without the cleaning process. Named after their payload in kilos, the three different Gecko Single Pad grippers (SP1, SP3 and SP5) work with leading small robots and COBOTs. The compact, single-pad design allows easy workpiece accessibility, even in tight spaces. With no electronics or air supply needed, the Gecko SP is a cost-effective, true plug-and-play solution. Seamless integration with the robot of your choice.

VGC10 ELECTRICAL VACUUM GRIPPER CUSTOMIZABLE

VGC10 – COMPACT, CUSTOMIZABLE ELECTRICAL VACUUM GRIPPER

- Flexible electric vacuum gripper with unlimited customization fits all your application needs

- Small, lightweight gripper is perfect for tight spaces but with plenty of power for objects up to 15kg

- No external air supply needed for reduced maintenance costs and faster deployment

Why VGC10 ELECTRICAL VACUUM GRIPPER?

The VGC10 electrical compact vacuum gripper has unlimited customization possibilities. It has changeable suction cup options too for nearly any application need. Smaller than the VG10, the VGC10 can fit into tight environments to extend your automation possibilities. And at half the weight of the VG10 but with the same payload, the VGC10 can lift small, odd-shaped, and heavy objects even with a smaller robot arm. The VGC10 features two independently controlled air channels that allow it to act as a dual gripper with pick-up and release in the same action, further increasing efficiency and reducing cycle time. With no compressor or air supply needed, this compact electrical gripper is easy to move, and simple programming makes it quick and easy to redeploy for greater production flexibility. Seamless integration with the robot of your choice.

VGP20- Powerful Electric Vacuum Gripper

POWERFUL ELECTRIC VACUUM GRIPPER IDEAL FOR CARDBOARD BOX PALLETIZING

- Industry’s most powerful electric vacuum gripper saves up to 90% over pneumatic grippers

- Ideal for palletizing boxes—including cost-saving, thinner cardboard—and handling irregular shapes and porous surfaces

- Built-in intelligence and multichannel functionality ensure failsafe, flexible operation

- Complete out-of-the-box vacuum gripper offers fast, easy deployment with any leading robot.

Why VGP20 Gripper?

VGP20 is the world’s most powerful electric vacuum gripper, with payloads up to 20kg (44.1 lbs) and none of the cost, complexity, and maintenance of pneumatic grippers. The VGP20 is ideal for palletizing cardboard boxes, including those made with thinner, more porous recycled cardboard, as well as bulky and irregularly shaped shipping bags. That helps shippers save even more, while also reducing waste.

Soft Gripper

SOFT GRIPPER – FLEXIBLE FOOD-GRADE ROBOT GRIPPER

- Explore new possibilities for food and beverage, cosmetics, and pharmaceuticals automation with certified food-grade soft gripper

- Easily handle a wide array of irregular shapes and delicate objects with flexible silicon-molded gripper

- Safely handle fragile and delicate objects for higher production quality and reduced waste

- No external air supply means no dust, no noise, no complexity, and no additional costs.

Why Soft Gripper?

The OnRobot Soft Gripper is able to pick a wide array of irregular shapes and delicate items, making it ideal for pick-and-place applications in food and beverage production, as well as manufacturing or packaging. The gripper is available with three interchangeable silicon-molded cups. From eggs to fruit, to bottles or cans, food and beverage automation just got easier. Like all OnRobot grippers, the Soft Gripper offers seamless integration with the robot of your choice. The Soft Gripper operates without an external air supply, for no additional costs or complexity, and none of the dust or noise generated by traditional vacuum grippers.

OnRobot Eyes

FLEXIBLE, ADAPTABLE 2.5D VISION SYSTEM

- Quickly and easily add vision to robotic applications with one-picture calibration, fast programming and seamless gripper integration

- Affordable, efficient 2.5D vision offers depth perception for varying heights or stacked objects

- Flexible, adaptable vision system with on-robot or external mounting is ideal for almost any collaborative application

- Easily sort, pick and place unstructured applications with high reliability using any robot arm

- One-shot detection for multiple objects minimizes cycle time

- Inspect objects using color and contour detection—with or without a robot, and ensure consistent quality

- Automatic landmarks enable dynamic working environments and mobile robot setups.

Why OnRobot Eyes?

On Robot Eyes makes it easy and affordable to deploy vision for almost any collaborative application. Eyes are ideal for sorting a variety of objects, CNC machine tending with metal parts that are defined by outer shape, and many other pick-and-place applications where orientation is important.

OnRobot Screwdriver

MULTIFUNCTIONAL ROBOT SCREWDRIVER WITH SCREW FEEDER

- Easy out-of-the-box setup, programming, and deployment on any leading robot

- Highly versatile and flexible, with fast changeovers for a wide range of screw sizes and lengths

- Precise torque control and intelligent error detection ensure quality and consistency

- Embedded axis motion control simplifies programming, speeds setup, and improves quality.

Why OnRobot Screwdriver?

You can easily automate assembly processes with the new intelligent On Robot Screwdriver for light industrial and collaborative robots. Intelligent error detection and multiple screw size handling will ensure consistent results and reduce your cycle time dramatically.

OnRobot Sander

FAST, EASY AND FLEXIBLE AUTOMATED MATERIAL REMOVAL

- Easy to deploy and program right out of the box for sanding, buffing and polishing

- Complete package includes everything needed for immediate use on a range of parts and materials

- Fast, automated sanding Grit Changer reduces downtime and labor

- Electric tools (no compressed air) boost efficiency and control.

Why OnRobot Sander?

Complete electric random orbital sander for almost any automated surface finishing application, from sanding and buffing to polishing and cleaning. The Sander is available with everything you need to get started right away, and operates without external air supply, for no additional costs or complexity, and none of the dust or noise generated by traditional air sanders.

HEX 6-AXIS FORCE/TORQUE SENSOR

HEX FORCE/TORQUE SENSOR – GIVING THE SENSE OF TOUCH TO YOUR ROBOT

- Flexible sensor extends automation possibilities to processes that weren’t previously possible

- High-accuracy sensor technology provides 95% better quality in insertion and assembly tasks.

- Easy programming even gets complex polishing tasks up and running in less than a day.

Why HEX 6-AXIS FORCE/TORQUE SENSOR?

On Robot 6-axis force torque sensors provide accurate force and torque measurements along all 6 axes. This gives you precise control when it comes to difficult assembly, polishing, sanding or deburring jobs. Additionally, the HEX software includes path recording, force control and special features for insertion tasks. This means reduced integration time for your production line. Our sensors are designed to fit most of the current industrial robot arms. Common applications are polishing, sanding, deburring, grinding and assembly, but it can also be used for teach-in and crash detection.

Currently available models: HEX-E /High Precision, HEX-H /Low Deformation, HEX-E QC, HEX-H QC.

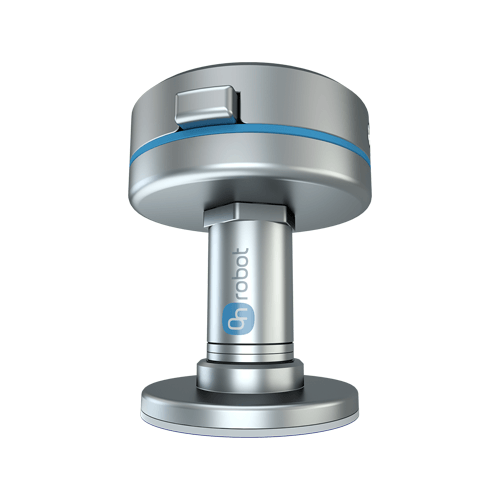

QUICK CHANGER

QUICK CHANGER – FAST TOOL CHANGING WITHIN 5 SECONDS

- Easy and fast tool changing in less than 5 seconds

- Fast re-deployment, no screwing, more up-time

- Integrated in all On Robot products.

Why Quick Changer?

The Quick Changer enables easy and fast tool changing. The Quick Changer can handle 20kg payload and has a low built-in height and weight. Patented reliable and with easy-to-use locking mechanism, extra safety locking structure and locking springs make the Quick Changer a unique product, ideal for all collaborative robot applications. With the Quick Changer you will have the easiest and fastest tool changer with everything you need within the box.

DUAL QUICK CHANGER

DUAL QUICK CHANGER – DUAL GRIPPING, MORE POWER FOR TWICE THE WORK

- Dual gripper speeds cycle time and can improve productivity by 50% or more

- Increased productivity offers faster payback, with ROI in as little as 3 months

- Increased up-time in CNC machine tending.

Why DUAL QUICK CHANGER?

The Dual Quick Changer enables you to use our end-of-arm tools together in a single cycle. With this innovative solution you can use two RG2 grippers or an RG6 gripper with a VG10 – it’s entirely up to you. Quickly and seamlessly switch between our tools to maximize the utilization of your robots with the Dual Quick Changer.

Accessories

Get an overview of available accessories for your collaborative robot application.

RG2 FINGER GRIPPER,

RG6 FINGER GRIPPER,

GECKO SINGLE PAD GRIPPER,

3FG15 FINGER GRIPPER,

SOFT GRIPPER,

VGC10 VACUUM GRIPPER,

VGC10 VACUUM GRIPPER,

ONROBOT EYES,

ONROBOT SCREWDRIVER,

QUICK CHANGER,

2FG7 FINGER GRIPPER

See the RG2 Gripper in Action