Manipulator & Docking Solutions

At Turbodynamics, engineering has the highest priority. The processes of the semiconductor industry are very familiar to us. With our global presence, we ensure seamless integration into your production.

Manipulators

Trolleys

Docking – Interface

Conversion Kits

P-Lift

Probecard -Loadboard Handling

We have implemented solutions worldwide at the largest semiconductor manufacturers in Asia, Europe and the United States.

We work closely with our customers on all levels, understand their requirements and deliver solutions. As an example, our Storage System offers a unique solution for handling probe cards in wafer production.

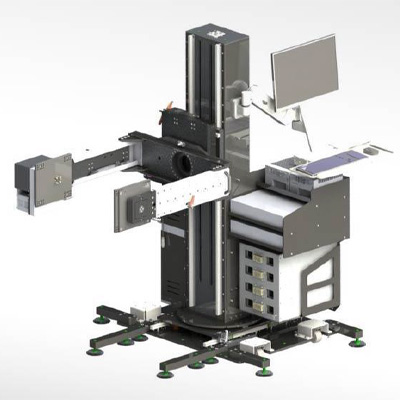

Universal Manipulator for Automatic Test Equipment

The main field of application for our Universal Manipulators is Wafer Testing and Final Testing in the semiconductor industry. Special focus lies on precise handling of Testheads weighing up to 750 kg. In combination with our Docking Systems, the Manipulators achieve a backlash-free coupling to chip handling devices within µm-range.

Manipulator Tiger M 250U

Key Features

- Operator friendly and intuitive usage

- Manually guided and/or motorized control

- Prepared for automated docking

- Modular footing and testhead mounting configuration

- Customized cable management for individual testhead applications

- Robust design and high-quality manufacturing

Weight capacity: up to ~250 kg / 550 lbs.

ATD Docking Systems

The reliable connection for ATE and Device Handling

We develop and produce Docking Systems for all common types of Probers and Handlers. We are also open to develop individual solutions for specialized test equipment.

Docking Systems by Turbodynamics are operator-friendly and maintenance-free.

All systems are compatible with many common OEM Docking Systems and suitable for a wide range of Test Systems. Like all our products the Docking Systems stand for quality and precision in Probe and Final Test.

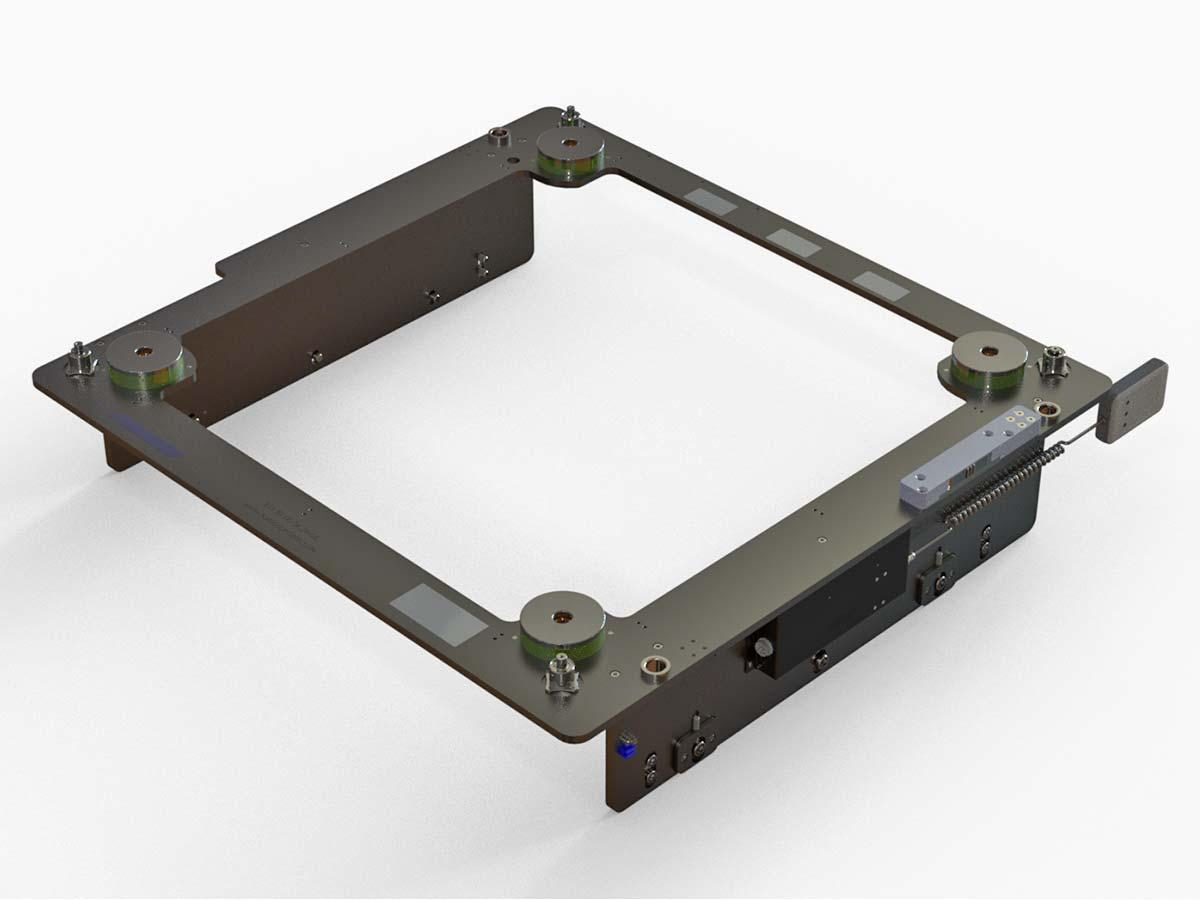

P-Dock® – the Benchmark for Docking in ATE Test

Our P-Dock® Systems are proven and in use worldwide – with more than 1000 installed units. Their unsurpassed efficiency is a benchmark in the semiconductor industry.

The P-Dock® System works with an accuracy of less than 10 µm. A pre-lock for optimal pre-centering and the extremely short Z-Stack distance ensures highest reliability.

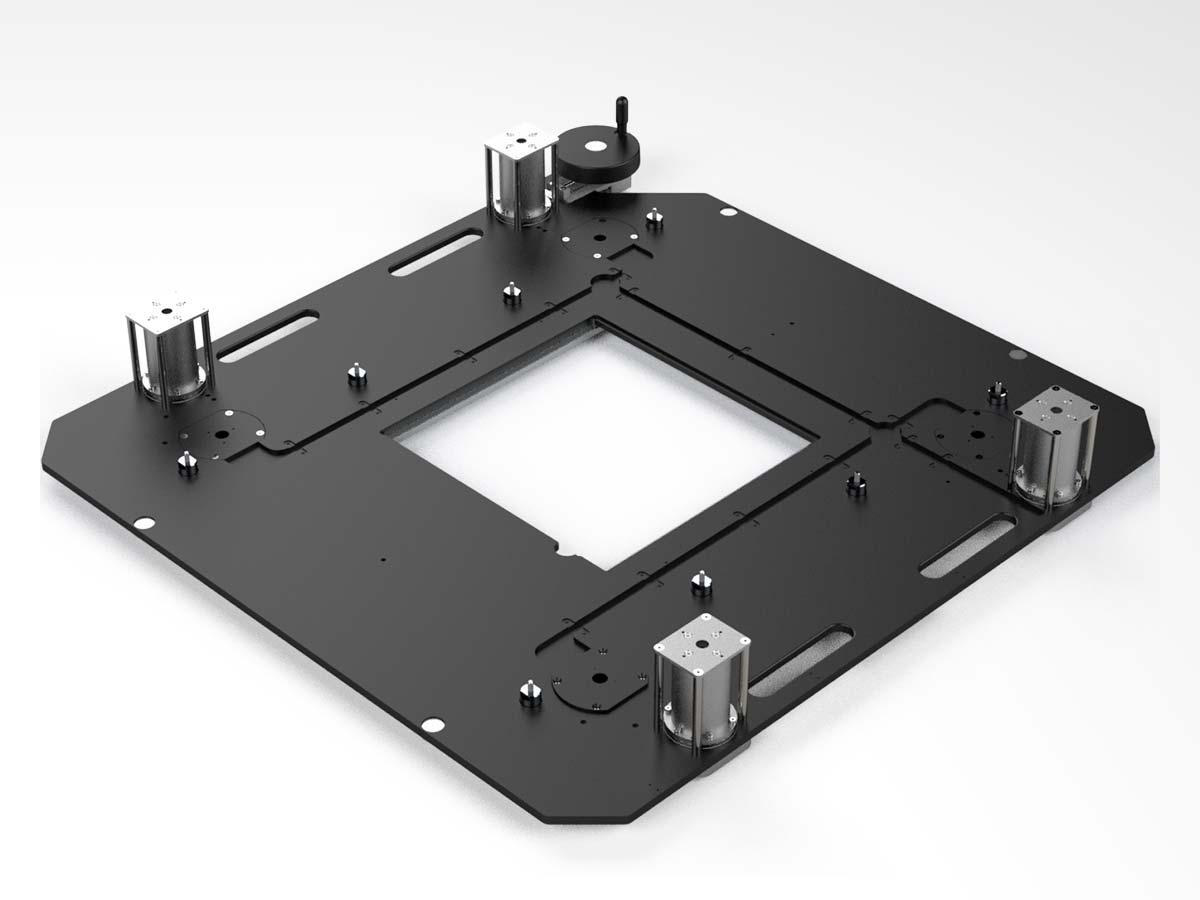

F-Dock – Final Test for highest demands

F-Dock Systems by Turbodynamics are specially developed for the Final Test. The robust design works without electricity or compressed air. In addition, the backlash effect of the Testhead is eliminated.

F-Dock is faster, more precise and can be handled with less manpower.

As a globally unique system, F-Dock uses a mechanical locking mechanism that adjusts to the Z-Stack of contacting.