Cleaning Equipment

AUTOMATION & INTEGRATION

Surfx Technologies offers atmospheric argon plasmas for high-volume manufacturing of semiconductor packages, printed circuit boards, automotive electronics, medical devices, and medical diagnostics. We provide handheld plasma tools for aerospace manufacturing as well. Our automated plasma machines are an excellent choice for in-line surface cleaning, activation, and adhesion improvement

Automated Plasma System

STA-10 for high-volume manufacturing of electronic components

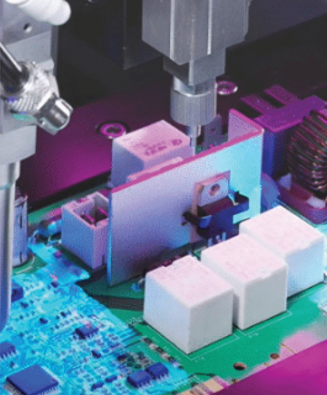

The STA-10iL automated plasma system is designed to clean and activate substrates for improved adhesion. It is ideal for semiconductor packaging and electronics manufacturing. The STA-10iL comes standard with in-line conveyance for high-volume manufacturing. An optional drawer can be installed for high-mix, low-volume production. Inside the STA-10iL, a three-axis gantry selectively applies the most advanced atmospheric plasma to your substrates. Surfx’s Atomflo™ controller operates with low voltage, radio frequency (RF) power, and generates a uniform, particle free, and electrically neutral plasma that is safe on the most sensitive electronics.

The STA-10iL has many options for in-line or batch manufacturing with full traceability:

- Oxygen plasma for organic clean

- Hydrogen plasma for metal oxide removal

- Cleanroom class 100 (10,000 is standard)

- Inert gas purge for reducing gas chemistry

- Substrate Heating and cooling

Atmospheric plasma sources

SPS-100

The SPS-100 is a linear beam plasma source designed to clean and activate substrates for improved adhesion. It is ideal for semiconductor packaging and electronics manufacturing.

Processes Improved by Plasma

- Conformal coating adhesion

- TIMs (Thermal Interface Materials)

- Optical bonding

- Staking

- Structural bonding

- Paint adhesion

- Wafer- and die-to-wafer bonding

- Wire bonding

- Thermocompression bonding

- Indium and tin solder reflow

- Over-mold adhesion

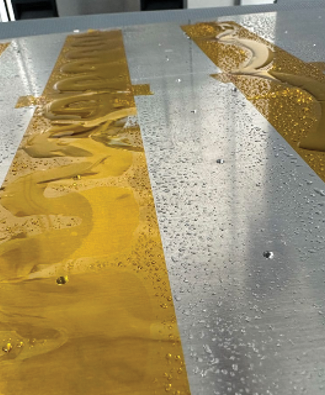

Wetting and adhesion

Improve adhesion of ink, glue, and coatings

Conformal coating

Eliminate voids, improve coverage over entire printed circuit board, and enhance coating adhesion

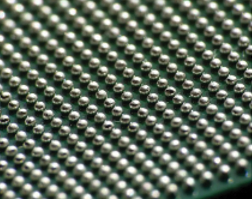

Flux-free flip chip

Remove oxidation from indium, tin. and copper micro-bump arrays using the atmospheric pressure hydrogen and argon plasma

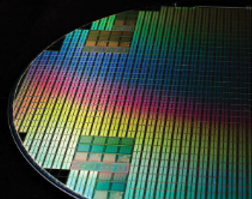

Hybrid wafer bonding

Activate glass films for direct fusion bonding without adding any particles to the wafer surface

Underfill

Activate surfaces underneath BGAs, CSPs or flip chips prior to dispensing underfill

Wire bond

Remove organic contamination from bond pads on lead frames prior to wire bonding

Molding

Activate lead frames and other packages for adhesion prior to encapsulating dies in an epoxy mold