Soldering and SMT Rework

Hand Soldering, Desoldering, & Rework Systems

Ultimate Performance Through Inductive Technology

Ultimate Performance Through Inductive Technology

CV-5210 & CV-510 Connection Validation Soldering Systems

CV-5210 & CV-510 Connection Validation Soldering Systems

Metcal offers two unique Connection Validation Soldering Systems featuring patented Connection Validation IMC formation technology, and SmartHeat power-on-demand

The CV-IOT Gateway Module with Connection Validation systems enables you to monitor and capture data at every station on your network, for maximum productivity and process control

GT90 & GT120 Best-in-Class Adjustable Temperature Soldering Systems. Metcal’s first adjustable soldering stations are high performance single-iron units with replaceable tip and cartridge options The GT Series applies Metcal’s expertise in inductive heating to an adjustable temperature soldering system for the time. This drives high-performance through improved:

- Time to temperature

- Temperature stability

- Thermal recovery

GT 90 / GT 120

Features and Benefits of Soldering Station

- Inductive heating systems offering best in class performance

- Adjustable Temperature

- Intuitive 4 button user interface

- Wide variety of cartridge and tip options

- Compact to minimize the workbench footprint

- Programmable password lock-out and temperature range limits

- Standby and sleep settings to increase tip life

- USB port to power accessories and firmware updates

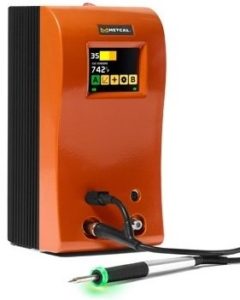

CV-5210

Features and Benefits of CV Soldering Station

• SmartHeat Power on Demand Technology

• Patented Connection Validation IMC Formation Technology

• 2.8” color touchscreen with bold graphics

• Communications Port for process traceability data and firmware graphics

• Precise tip temperature display

• Integrated Net Power Meter and power graph

• Patented Chip-in-Cartridge technology

° Closed loop bi-directional communication

° Stores and records cartridge attributes

° Provides traceability information

° Protects power supply from non-conforming cartridges

° Backwards compatible with MX series power supplies

• Password protection

MX-5210 Soldering Station and Rework System

New dual port simultaneous soldering and rework system is highly effective for soldering applications including: lead-free, high mass components or boards, thermally sensitive components requiring low operating temperature, high volume production soldering and touch-up soldering operations. In addition, the MX-5210 can be used for conduction rework of SMDs when using SMTC series soldering cartridges simultaneously.

Features and Benefits Soldering Station & Rework System

- Can be operated with two hand pieces dynamically sharing the 80 watts output power based on demand adding even more application flexibility and speed

- Configured with the Metcal advanced soldering and rework hand-piece

- Microprocessor controlled power supply providing more power for challenges such as high mass components, multi-layered boards and lead-free solders

- Improved ergonomics with lightweight hand-pieces

- Greater process control with SmartHeat® Technology

- ESD safe with incoming AC ground monitoring circuitry

- Built-in power indication meter with digital display and bar graph that dynamically provides the operator with feedback on the status of the soldering operation

- Metcal TipSaver™ workstand improves tip life with its ’Auto-Sleep’ function

The PS-900 Production Soldering System

Metcal’s PS-900 Soldering System, powered by SmartHeat® technology, is a powerful, cost-effective soldering system with a small benchtop footprint. The PS-900 is designed for lead free soldering, multi-layer boards, and thermally demanding components.

Metcal’s PS-900-Solar System is a specific package designed for solar cell applications, with an extended cable, and a specially designed high thermal demand STV-DRH440A hoof tip.

Key features and benefits

- SmartHeat® temperature control

- Ergonomic, lightweight handle

- Rugged cast aluminum housing

- Added Planting thickness to tips

- Low cost, quick-change heater coil

MFR-1100 Single Output Soldering Station & Rework System – Cartridge Hand-piece

METCAL’s Soldering Station, MFR-1100 Single Output Series is highly versatile in that it can be used with either a soldering tip, cartridge or tweezers and offers a choice of four hand-pieces. The MFR-1110 comes with one cartridge soldering hand-piece. The cartridge hand-piece uses small diameter cartridges for easy access and includes a full range of cartridges, including SMD rework.

Features and Benefits of Soldering Station:

- SmartHeat® Technology provides exceptional power for high thermal demand applications.

- Four hand-pieces available for increased application solutions for soldering and rework on one system

- Each hand-piece has a comprehensive range of cartridges or tips for maximum flexibility

- Hand-pieces are ergonomic for operator safety and comfort

- Small Bench Top foot print

- Can be combined and locked with its brother the MFR-2200 dual output series for increased application solutions for soldering and rework

METCAL’s Soldering Station, MFR-1350 features a soldering hand-piece and a desoldering gun. The power supply has an internal pump providing 0.7 bar of vacuum suction force combined with Smartheat® technology that makes soldering, rework and through-hole desoldering easy and safe.

Features and Benefits of Soldering Station:

- Self-contained powerful pump

- 2 in 1 ergonomic and flexible hand-piece: pencil or pistol

- Collection chamber with larger capacity

- Smart collection chamber for quick and easy change

- Dual switchable output

- Powered by Smartheat® Technology

The MFR-2200 Series features dual-output capability allowing users to select operation of one handpiece or two handpieces simultaneously.

The MFR-2200 Systems offer a choice of three handpieces, however two additional hand-pieces including the desoldering option are also available as upgrade kits.

Features and Benefits of Soldering Station:

- SmartHeat® Technology provides exceptional power for high thermal demand applications.

- Single or Dual simultaneous outputs allow for single or dual hand-piece use.

- Four hand-pieces available for increased application solutions for soldering and rework on one system.

- Each hand-piece has a comprehensive range of cartridges or tips for maximum flexibility.

- Hand-pieces are ergonomic for operator safety and comfort

The system utilizes SmartHeat® Technology, wherein each cartridge is equipped with a self-regulating heater which ‘senses’ its own temperature and closely maintains its pre-set idle temperature for the life of the heater-tip. The tip temperature is determined by the inherent metallurgical properties of the heater; no external adjustment or equipment is required. The MX-500 retains switchable dual port, 40W operation while introducing numerous new features in a new housing.

FEATURES AND BENEFITS

- Integrated Power Indication Meter: a built in net power meter which will display a graphical and numerical representation of the power applied to the cartridge.

- User Programmable PowerSave Mode: the time to enter PowerSave Mode is adjustable from 10 to 120 minutes.

- Ground Fault Interrupt: AC ground monitor detects power line ground failures and immediately alerts the operator and shuts down the system. Only after the power line ground has been restored, can the MX-500 be restarted and soldering operations can be resumed.

- Universal Power Supply: automatically senses the input line voltage and adjusts accordingly, which allows for worldwide operation without adaptors or a change in performance.

- Compatibility with all MX products: the MX-500 redesign allows full compatibility with existing and previous MX upgrade kits, tip-cartridges, hand-pieces and accessories.

- Greater process control with SmartHeat® Technology

- Reduced space requirements

HCT-910 Hot Air Rework System

Maximize process control and productivity with the convection system built to ensure ease-of-use and operator safety.

Key Features & Benefits

- Fast Time-to-Temperature 900 W of power

- Fully Adjustable Temperature Range 50 – 600 °C

- Unrestricted Airflow Up to 120 l/m (4.24 cfm)

- Intuitive User Interface Easy programming & adjustments

- “On-the-fly” Manual Mode Adjust temp & airflow with one dial

- Tool-less Nozzle Swapping Compatible with HCT-900 nozzles